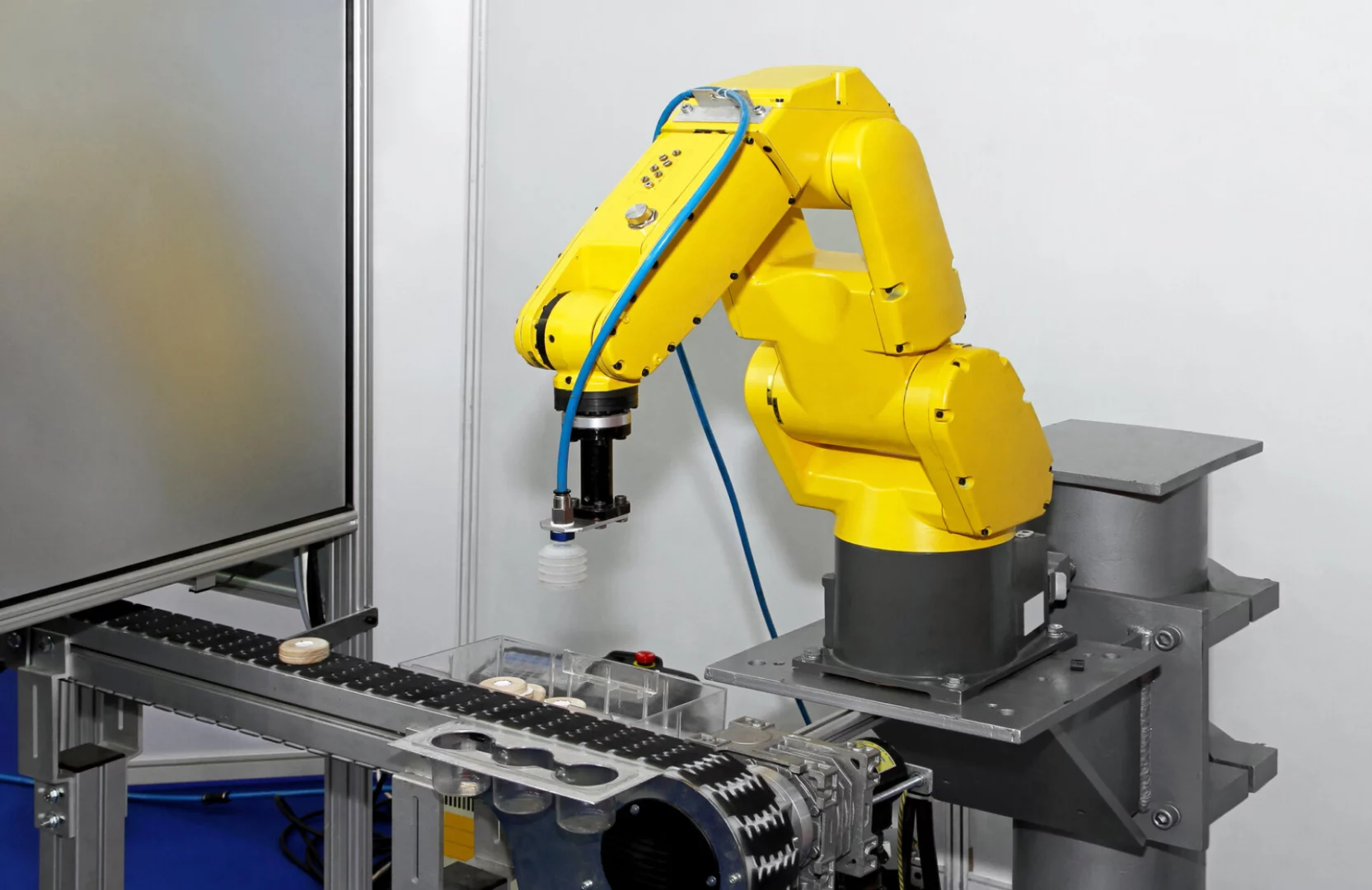

The robotisation and PLC programming competence at the Institute of Machine Tools and Mechatronics is primarily intended to provide the installation, programming and preparation of case studies for industrial robots and the programming of PLCs. In line with current requirements, industrial robots and PLCs are also integrated into several manufacturing processes, thus increasing productivity, and such systems are suitable for compensating for today’s shortage of human labour.

InnoME TTC Kft.

Corporate contact

Contact us