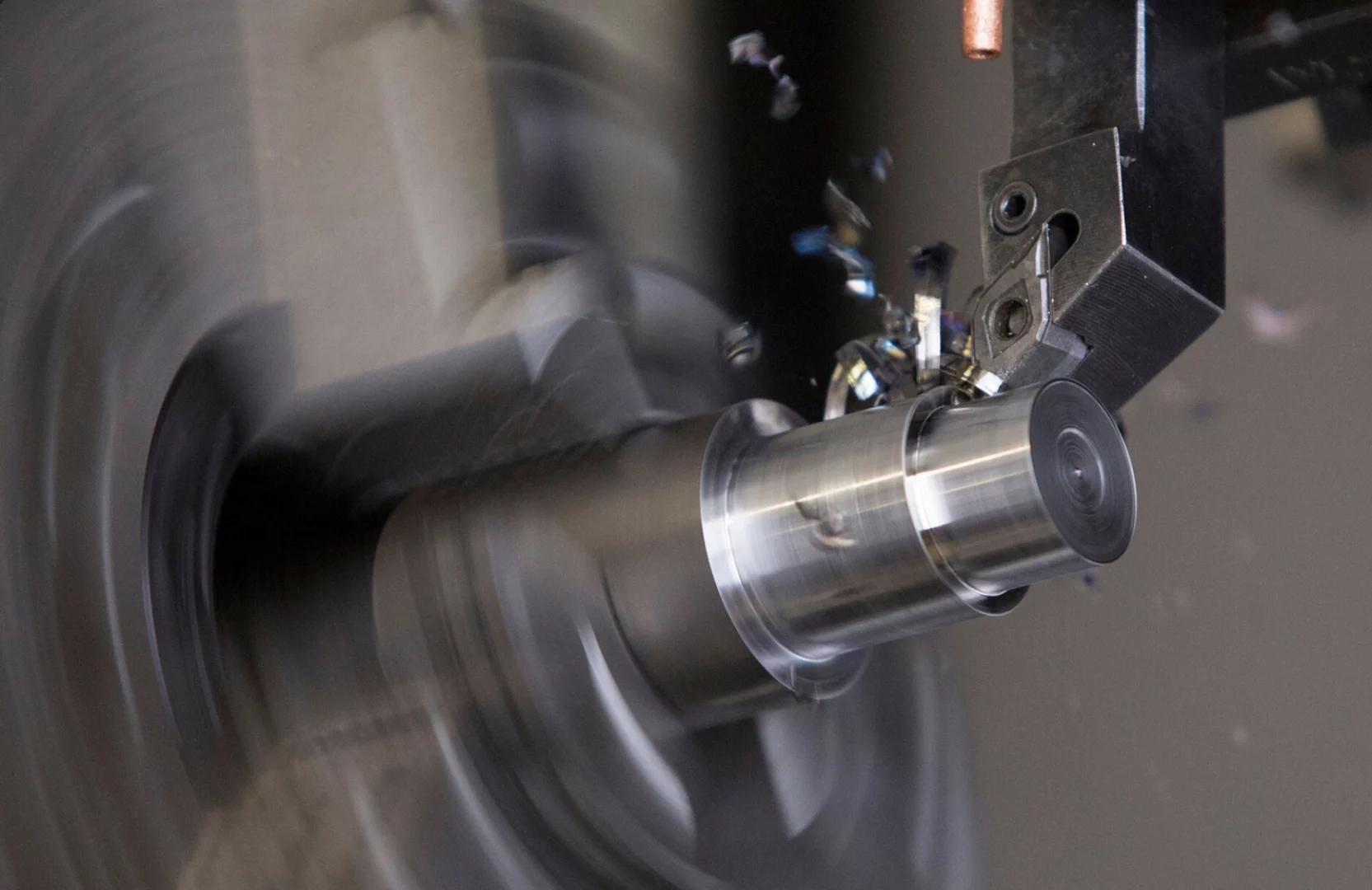

The CAD/CAM competence at the Institute of Machine Tools and Mechatronics primarily covers the use of design systems and their application in the design of production equipment, special-purpose machines, machining equipment and machine units. In today’s world, it is a basic requirement to be able to complete a design task as quickly and efficiently as possible. Computer-aided design has great significance in industrial practice when designing tools, equipment,and machining procedures.

Webpage of FIEK Research Institute

Contact us